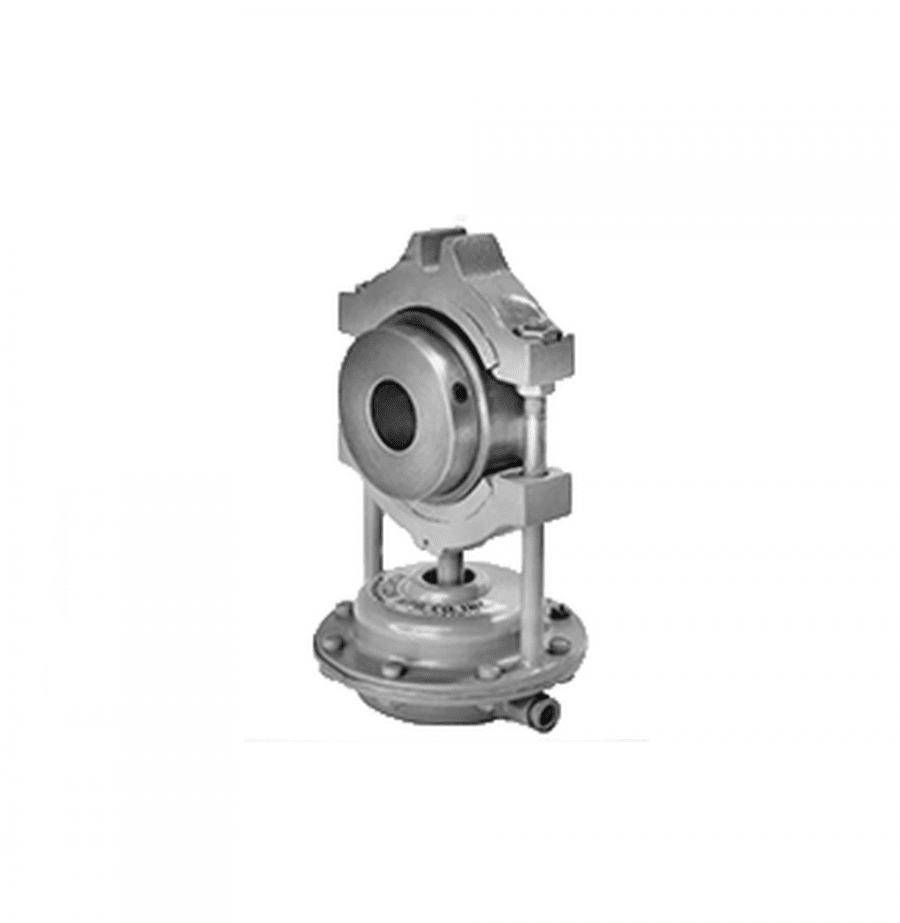

Description

Web sensor is the input devices used with tension control systems and web guide systems. web tension sensors include load cells for measuring the force applied to a sensor roller, roll diameter sensors, and rotary sensors used with dancer systems. web guide sensors include both edge and line following sensors.

Web sensors detect the location of the edge of a moving web and send a signal to a controller to drive an electric actuator that adjusts the roll or roller angle to keep the web tracking precisely through a process to get consistent results. They can be optical, ultrasonic, or line following types depending on the material.

Web guide sensors detect the location of the edge of a moving web and send a signal to a controller like Nexen’s AE120 to drive an electric actuator that adjusts the roll or roller angle to keep the web tracking precisely through a process to get consistent results. They can be optical, ultrasonic, or line following types depending on the material.

Benefits of Automated Web Tension Control

Lack of tension control can result in:

- Wrinkles

- Web breaks

- Poor process results

- Interweaving (slitting)

- Poor print registration (printing)

- Inconsistent coating thickness (coating)

- Length variations (sheeting)

- Material curl during laminating processes

- Roll defects (telescoping, starring, etc.)

To Know more information about this product please Contact Nayagi.in