Description

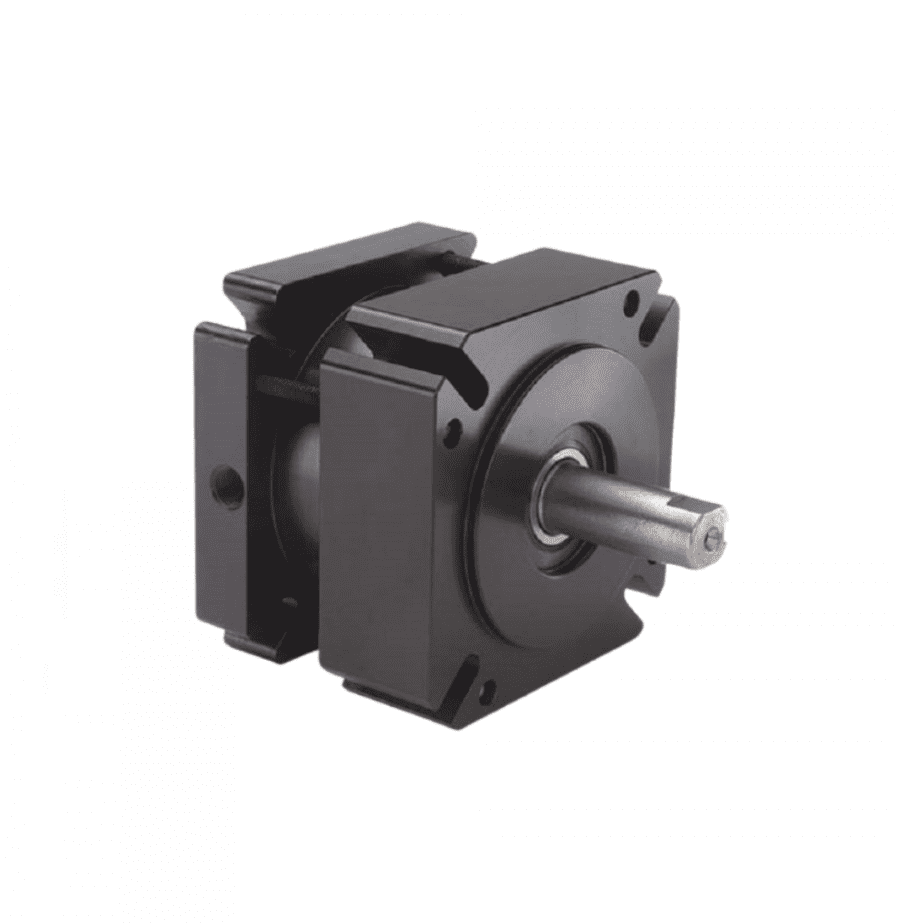

Harmonic Gearhead offer true zero backlash, high reduction ratios of 50/80/100/120:1, and high load capacity in a very compact package. Harmonic Gearhead utilize the best cross roller bearing technology for the highest rigidity and load capacities. They are available in ISO9409 flange mount or with an integrated RPS pinion. The integrated pinion models offer the ultimate in RPS system performance and simplify installation.

Strain wave gearing (also known as harmonic gearing and harmonic drive) is a type of mechanical gear system that can improve certain characteristics compared to traditional gearing systems such as helical gears or plantary gears.

The advantages includes no backlash, high compactness and light weight, high gear ratios, reconfigurable ratios within a standard housing, good resolution and excellent repeatability (linear representation) when repositioning inertial loads, high torque capability, and coaxial input and output shafts. High gear reduction ratios are possible in a small volume (a ratio from 30:1 up to 320:1 is possible in the same space in which planetary gears typically only produce a 10:1 ratio).

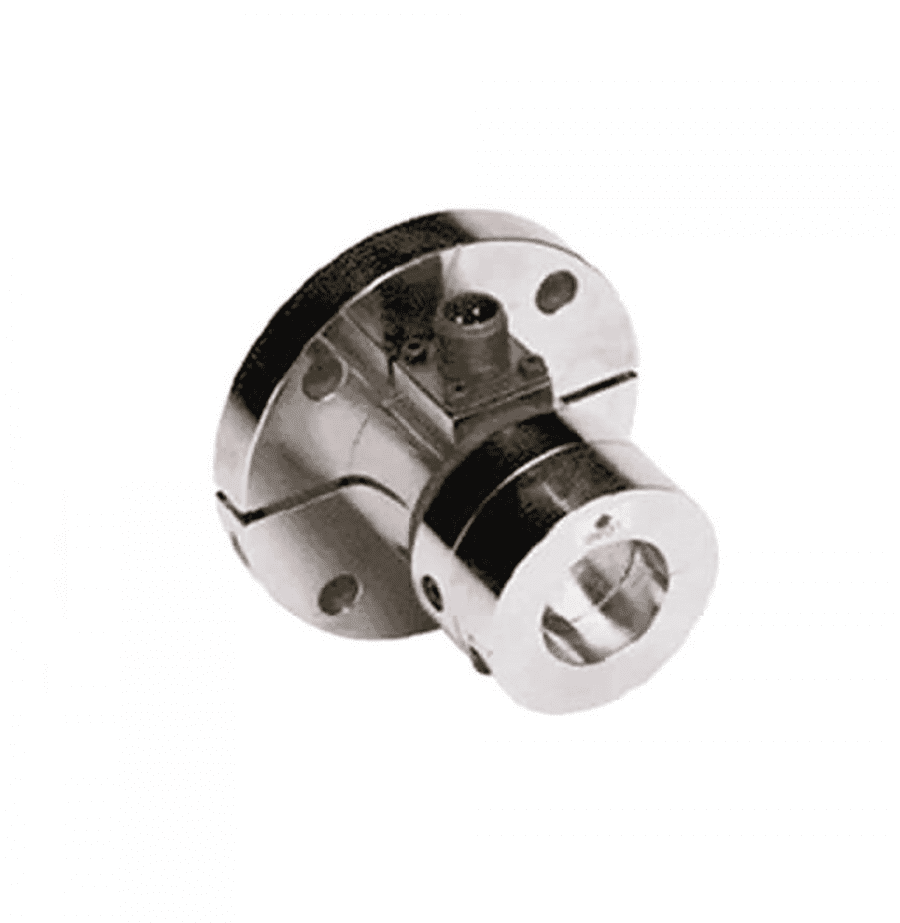

The strain wave gearing theory is based on elastic dynamics and utilizes the flexibility of metal. The mechanism has three basic components: a wave generator (2 / green), a flex spline (3 / red), and a circular spline (4 / blue). More complex versions have a fourth component normally used to shorten the overall length or to increase the gear reduction within a smaller diameter, but still follow the same basic principles.

The wave generator is made up of two separate parts: an elliptical disk called a wave generator plug and an outer ball bearing. The elliptical plug is inserted into the bearing, forcing the bearing to conform to the elliptical shape but still allowing rotation of the plug within the outer bearing.

The flex spline is shaped like a shallow cup. The sides of the spline are very thin, but the bottom is relatively rigid. This results in significant flexibility of the walls at the open end due to the thin wall, and in the closed side being quite rigid and able to be tightly secured (to a shaft, for example). Teeth are positioned radially around the outside of the flex spline. The flex spline fits tightly over the wave generator, so that when the wave generator plug is rotated, the flex spline deforms to the shape of a rotating ellipse and does not slip over the outer elliptical ring of the ball bearing. The ball bearing lets the flex spline rotate independently to the wave generator’s shaft.

To Know more information about this product please Contact Nayagi.in